THE NEW OIL SIGHT GLASS

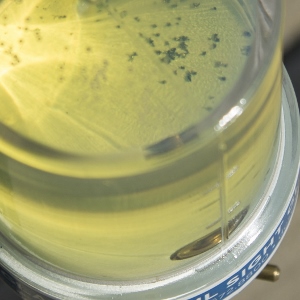

With the new and improved oil sight glass (OSG), our engineers reimagined how an oil sight glass plays a critical role in early detection of contamination and allows for constant monitoring of what’s in your oil that can decrease equipment life. Users have an immediate, crystal-clear visual inspection of the oil and a magnified view of the presence of sediment, thanks to an innovative white bottom design. The new OSG has the versatility to be installed vertically or horizontally to a drain port depending on space needs for the application. With the addition of indication marks on the side of the bottle, you can now quickly and easily monitor the rate of water accumulation.

NPT, METRIC & BSPP SIZESMaterial

Recommended Temperature Range

Maximum Operating Pressure

Chemical Compatibility

Available Options

|

| Part Number | Description | Overall Length | Outside Diameter | |||||

|---|---|---|---|---|---|---|---|---|

| Sizes | ||||||||

| DC-OSG1X250 | 1 oz X 1/4" | 3.0 in / 7.62 cm | 1.72 in / 4.37 cm | |||||

| DC-OSG1X375 | 1 oz X 3/8" | 3.0 in / 7.62 cm | 1.72 in / 4.37 cm | |||||

| DC-OSG1X500 | 1 oz X 1/2" | 3.0 in / 7.62 cm | 1.72 in / 4.37 cm | |||||

| DC-OSG3X250 | 3 oz X 1/4" | 3.15 in / 8.0 cm | 2.50 in / 6.35 cm | |||||

| DC-OSG3X375 | 3 oz X 3/8" | 3.15 in / 6.35 cm | 2.50 in / 6.35 cm | |||||

| DC-OSG3X500 | 3 oz X 1/2" | 3.15 in / 6.35 cm | 2.50 in / 6.35 cm | |||||

| High-Volume Vertical Acrylic Sizes |

||||||||

| DC-OSG16X500 | 16 oz X 1/2" | 5 in / 12.70 cm | 3.5 in / 8.89 cm | |||||

| DC-OSG32X500 | 32 oz X 1/2" | 5 in / 12.70 cm | 4.5 in / 11.43 cm | |||||

NOTE: Vertical and horizontal acrylic available in 1 oz and 3 oz sizes while supplies last.

- Pumps

- Gearboxes

- Storage Tanks

- Fluid-Lubricated Machinery

Do I still need a desiccant breather if using the Oil Sight Glass?

Yes. Desiccant breathers prevent moisture and contaminants from entering the fill port of equipment and pull moisture from the headspace. However, a desiccant breather cannot remove large amounts of water already mixed into the oil. That is why combining the use of desiccant breathers with oil filtration and an OSG to isolate and remove free-flowing water from the oil is best practice. Additionally, the OSG will act as an early indicator of a contaminants problem.

How durable is polyamide?

Polyamide is extremely durable and impact resistant. With excellent weathering and UV resistance, it is capable of withstanding years of exposure to sun, rain and other extreme conditions.

Does the Oil Sight Glass work with all oils?

Yes, the OSG will collect sediment and free-flowing water from any oils. They are best used with high-quality synthetic oils, as synthetics tend to do a more efficient job separating water.

Does the Oil Sight Glass replace the need for oil filtration?

While the OSGs will isolate and remove free-flowing water, it is still recommended that you utilize other filtration systems to remove all water contamination from your oil. The OSG will be an early indicator of contamination problems and can help find the source of such problems, but the OSG alone will not prevent moisture from entering your reservoir or remove any water that has become emulsified in the oil. Contact us at sales@descase.com for more information on filtration systems.

Can the Oil Sight Glass replace my oil sampling program?

Oil sampling and analysis is still recommended, as it is best practice. The OSGs are part of a comprehensive preventative maintenance program, and they will show users early indications of various forms of contamination.

Can I pull an oil sample from the Oil Sight Glass?

Water and other contaminants tend to sink to the bottom of a reservoir. Because of this, samples taken from the OSG will typically be “dirtier” than the rest of the oil in the reservoir. Best practice dictates that a sample should be drawn from the center of an oil reservoir. Sampling tubes can be utilized in conjunction with the OSG to draw a representative oil sample to be analyzed.

Can I use the Oil Sight Glass in freezing conditions?

The OSG can safely be used in temperatures as low as -40˚F as long as they are not allowed to fill completely with water.

I’m concerned about the Oil Sight Glass breaking. What can I do to prevent this?

Although very durable and impact resistant, it’s best to install the OSG in a location that is protected from mobile equipment or other high-impact hazards. It is also recommended that users install a ball-valve between the drain port and the OSG. The ball-valve allows instantaneous shut off of oil flow if necessary.

How can I clean/replace the VOA products without having to drain the oil from my equipment?

Installing a ball-valve between your drain port and the OSG will allow users to shut off the flow of oil in order to clean or replace the product. Cleaning the products typically requires just soap and water. Cleaning agents should be avoided, as they can cause fogging, crazing and degradation of the optical quality of the acrylic.